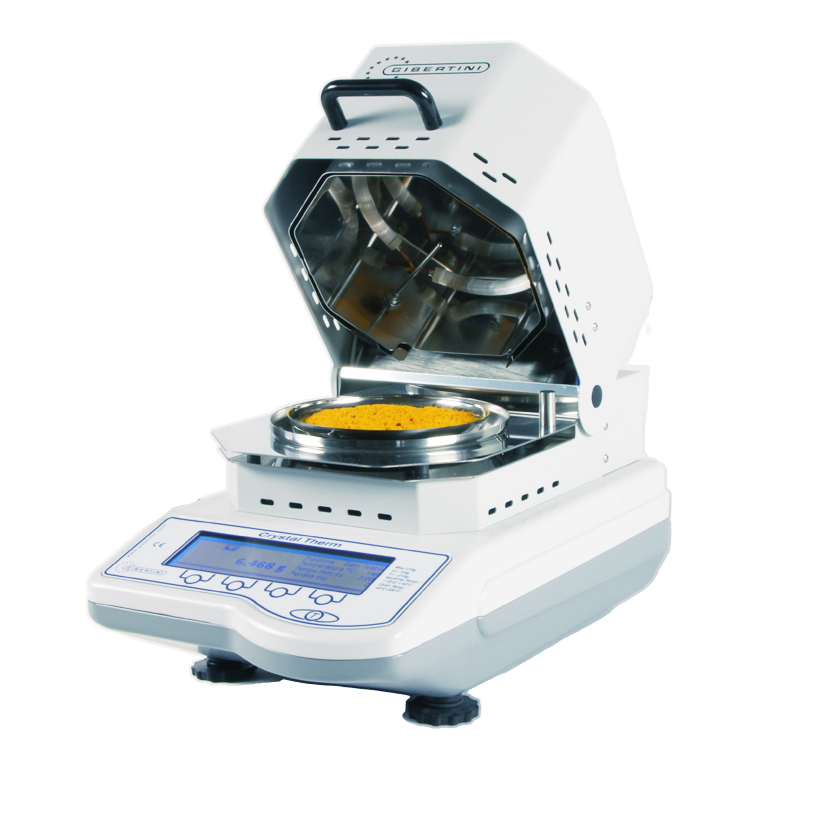

CrystalTherm

The Gibertini Moisture Analyzer for the determination of humidity and dry content

The Gibertini Moisture Analyzer for the determination of humidity and dry content

CRYSTALTHERM Moisture Analyzer is a Loss on drying system based on the measurement of the percentage of humidity on the weight difference with the principle of controlled drying of the sample, through a process of heating and constant control of weight variations.

Its main use is in the Food , Chemical and Pharmaceutical sector where the moisture and dry residue values determine the quality of the product and are subject to regulations and tolerances defined by national and international regulations and can reveal properties of the material relative to purity, concentration, stability, shelf life, and nutritional value.

This infrared Moisture analyzer has been designed to be used in the food, industrial, professional or laboratory sectors. Determines the dry matter after the drying process of the previously weighed sample. During the process you can see on the display the decrease of the moisture content. The moisture analyzer is also an ideal tool to accurately determine the consistency of materials and volatile and fixed substances.

Equipped with a Gibertini scale with maximum capacity of 100g or 200g with 1 mg resolution and oven temperature from 40 ° to 200 ° C, it is able to determine the percentage of humidity with an accuracy of 0.01%.

| Heating | Infrared |

| Capacity | 100g - 200g |

| Accuracy | 0.001g |

| Accuracy % | 0.01 % (minimum weight 10 g) |

| Repeatability % | ±0.02 % (minimum weight 10 g) |

| Temperature Range | 40°÷200° C (Increases 1°C) keyboard selection Celsius / Fahrenheit scale |

| Drying Method | Timer / Data Stable |

| Metods / Drying curve | 10 |

| sample minimum weight | 500 mg |

| Standard equipment |

1. Tare the empty weighing pan

2. Add the sample and arrange it evenly on the plate

3. Select a method from the library (10 storable methods) or Set a new one (Functions)

4. Press the Measure button to start the drying process and get accurate results in minutes

At the end of the test CRYSTATHERM will stop and the results will be stored on the display

All laboratory scales Gibertini can be supplied with :

to ensure compliance with the required standards and the reliability of the results ( GMP, GLP, Ph.Eur ).

Quality Service| Model | Capacity | Division | Accuracy % | Repeatability | Minimum Weight | Pan | Output |

|---|---|---|---|---|---|---|---|

| CrystalTherm 100 | 100 g | 0.001 g | 0.01 % | ± 1 mg | 500 mg | Ø 120 mm | RS232 |

| CrystalTherm 200 | 200 g | 0.001 g | 0.01 % | ± 1 mg | 500 mg | Ø 120 mm | RS232 |

For every need, certified masses are available, customizable weighing plates , sample holders and Software specially designed to improve and speed up the weighing processes. It is also possible to combine them with Anti-vibration weighing tables and Printers .

| Serial output | RS232 configurable |

| Operating temperature | 40÷200°C |

| Supply voltage / power | 230 VAC/50 Hz - 350 watt |

| Total Dimensions (L x W x H) | 210 x 355 x 300 mm |

| Net weight | 9 kg |

The following accessories are available for all instruments of the CrystalTherm series:

CRYSTALTHERM series moisture analyzer is essential for determining the dry matter by drying the sample to obtain the humidity. In the food sector it is used to determine product quality and compliance with national or international standards or tolerances.

Milk and Canned Foodfor the determination of the WATER CONTENT IN DAIRY PRODUCTS AND FORAGE FOR FOOD:

Fruit and Vegetable SectorIt is important to detect the initial moisture content in the raw materials which together with the Sugar content, Acidity, Total soluble solids is an important factor in determining the quality of the product.

Cereal and feed sectorto determine the dry residue and moisture. Humidity is an important factor for evaluating the Shelf-Life of the finished product. The CRYSTALTHERM moisture analyzer operates according to the official method for determining the humidity in grain cereals, floured Toro and G.U. n.145 of 21/06/85 | AACC METHOD 44-15A mod

Coffee Industry

Coffee Industry

After water Coffee is the most consumed drink in the world . To guarantee quality and cost control in coffee production, it is necessary to know the exact degree of humidity during the individual steps in production. The coffee beans are in fact marketed on the basis of weight and the amount of water contained in this product is decisive for being able to define the price. In many countries consumer rights laws have set the moisture content threshold in the product to a maximum of 5% . Coffee QC control as a raw material must also be carried out during the storage and transport phases: it should not exceed a moisture content of 13%, to avoid the danger of fermentation.

Moisture in rice is an analytical parameter that should always be known and that can be determined for different purposes. It is one of the factors that determines the good conservation but also for the quality of the product and no less important, for the definition of the price. Moisture can be determined in all forms of rice: paddy, husked, processed, parboiled, flours and by-products. An accurate measurement of the humidity of the paddy is important in the phases of harvesting, drying, storage and industrial processing. It is crucial to provide the result of other analyzes: proteins, amylose, fats, etc., referring to the dry weight of the sample. The determination of humidity with the Gibertini CRYSTALTHERM moisture analyzer takes place by direct measurement according to UNI EN ISO 712: 2010 by drying at a specific temperature. This analytical method is rigorous and provides precise and accurate results.

The analysis of the chemical and physical characteristics of biomass begins immediately after harvesting, in which the average humidity and ash content are determined

The crop residues have intrinsic characteristics that make them different both from the main products from which they derive and from any co-products. The main differences concern:

CONDITIONING AND DEHYDRATION OF SLUDGEDetermine the forms of water by drying test, with gravimetric technique subdivision of water into categories

depending on the intensity of the bond forces interacting between water and solid particles:

The treated sludge is dried under controlled temperature conditions (40 ° C) into the CRYSTALTHERM equipped with a precision balance and able to maintain a constant air flow. From the study of the evaporation curve, obtained by continuously measuring the loss of weight of the test sample, it is possible to determine the quantity of free and bound water.

Each textile fiber is characterized by the nature of the fiber itself and by a quantity of water that is present in it. The property whereby textile fibers as such or processed absorb a part of humidity from the atmosphere in which they are found, is called "hygroscopicity of textiles".

International regulations define what the humidity of a textile must be to have the same characteristics not only for the purposes of commercial transactions (do not sell water instead of yarn) but also to obtain machining with constant characteristics. The recovery rate and humidity value is defined for each textile fiber.

The recovery of humidity expresses the aptitude of the textile fibers to absorb and retain water. Indicates the hygroscopicity of the fibers.

The problem facing the textile industry is that of having yarns with constant and uniform humidity since, both for the different quality of the raw materials and for the different environmental conditions in which the yarn is produced.

When the yarn passes from the spinning phase to the next processing phase, it is essential to check the humidity of the yarn, checking the recovery rate by treating it in a manner such as to guarantee conventional values.

Some pharmacopoeias describe tests to be carried out in order to proceed with the identification of a botanical raw material that can contribute to the identification or otherwise contribute to the verification of the quality of the raw material:

Characteristics of the raw materials used and of the semi-finished productBeing very greedy for water, probiotic semi-finished products must respect more restrictive humidity limits than the processing of other products. Normally both the humidity is evaluated, which determines the amount of water present in the analyzed product, and the water activity (Aw), which identifies free extracellular water. The determination of the latter seems to be more significant so it is very important to be able to guarantee an Aw of the semi-finished product of less than 0.5%

Meat, Fish, Eggs, Milk, Cereals, Legumes, Fats and Oils

Seeds, Vegetables, Fruits, Raw materials (corn, wheat, coffee, soy, cocoa)

Raw materials analysis, active ingredients, compliance with pharmacopoeia regulations

Wine, Beer, Spirits, Juices, Soft Drinks, Energy Drinks, Sport Drinks

Water Analysis, Filters (PM10), Soil.

Research laboratories. science faculties, chemistry, physics, materials sciences

Raw materials analysis, Dosage/formulations, Creams, Solutions, Waxes

Gold and Precious, raw materials analysis

Dosing, Formulation, Polymer Analysis, Varnishes, Paints, Coatings, Inks

Clinics (Pre-analytical, Analysis, Post-analysis), Pharmacological, Forensic

Plastics, Detergents, Ceramics, Lubricants, Petroleum, Reagents

Buttons, yarn count, moisture determination

Goods receiving, creating dough, weighing glazes, slabs, tiles

production, formulation and quality control

analysis, weight, drugs density, narcotics, splinters

energy efficiency, special waste